CHANNEL LINING FOR EROSION CONTROL

What Are the Types of Lined Channels?

At Gabion Supply, we specialize in offering a wide variety of channel linings to meet a wide range of requirements. We understand that it's essential to line channels with a durable, weather and abrasion-resistant material to prevent soil erosion and wind ingress.

Concrete channel linings are perfect for larger-scale channel erosion control applications and provide the longest-lasting solutions with the least maintenance required. Our concrete channel linings are strong enough to withstand significant overlap between layers of concrete for the greatest strength and durability in excess weather conditions.

We provide channel-lining products, including gabion baskets, gabion mattresses, channel linings, AquaRockBags, and revetments for channels.

At Gabion Supply, our channel lining solutions mitigate the effects of erosion caused by runoff, so our materials can prevent topsoil loss, soil instability and expansive soils. For those seeking channel-lining design solutions and channel-lining products and services, you can trust that Gabion Supply will provide quality solutions at the right price.

Channel Lining Applications

Channel lining in stormwater systems can help manage flooding by absorbing the rainwater and slowing down the storm surges. It can also collect sediments and ensure they don't reach canals, rivers, and other waterways. In irrigation systems, canal lining or channel lining can make the system more efficient because it can prevent loss of irrigation water. Weeds can also grow, reducing water flow and channel lining can help prevent this.

On the roadside, vegetation as a long-term channel lining may be a good option because roads are mostly dry. Other flexible linings, such as gabions or wire-enclosed riprap, can also be used to prevent erosion.

What Makes Channel Lining Different From Rigid Wall Solutions?

Channel lining is important in our field, but it's different from rigid wall solutions. While a wall protects the stormwater flow, channel lining helps form a protected course that offers an environment suitable for vegetation and natural resources to flourish. With channel lining, plants can still flow with the terrain allowing water to flow more naturally than rigid walls.

With channel lining, your channel system won't appear as obtrusive and heavy as a rigid wall system. It helps to make the channel look more natural and has a pleasant overall aesthetic. Channel lining helps your project look like a cohesive unit without detracting from the beauty of the surrounding landscape.

Channel lining is an excellent solution to the stormwater control needs of your project and can provide the results you need with the look you desire.

What Is Channel Lining and Why Is It Important for a Project?

Channel lining is a vital part of any construction project. It helps keep soil, gravel, and other materials contained and can also help with proper drainage and erosion control. With channel lining, a durable barrier goes between the edges of a channel and the fill material used to make the sides of the channel. This barrier prevents water and other materials from washing away from the edge of the channel. The barrier can also help to improve water flow, keeping sediment from entering and clogging the channels.

It is crucial to use quality materials for the channel lining to withstand wear and tear and other elements. At Gabion Supply, we offer several types of channel lining material to choose from, so you can ensure your project is durable and protected.

What Materials Are Channel Lining Made Out Of?

Channel lining comes in various materials depending on your project needs and requirements. Some of the most commonly used materials are high-strength, corrosion-resistant metals. These materials can combine with wire rope or textiles to provide superior support and strength. Other options include flexible synthetics like reinforced plastic, elastomeric membranes, or non-woven fabrics. AquaRockBags are constructed of abrasion and UV-resistant virgin HDPE materials with a performance lifetime of over 50 years when properly installed. These materials are strong, lightweight and resistant to abrasion, ensuring that your channel lining lasts for years.

No matter what kind of material you decide to use, our experts at Gabion Supply can help you determine the right option for your channel lining needs. Our team can work with you to customize the right design for your project so that you get the optimal performance from your channel lining solution.

What Are the Benefits of Channel Lining Versus Other Options?

At Gabion Supply, we're passionate about channel lining, which has many benefits over other options, such as concrete linings. Channel lining has excellent resistance to weed growth, making it much easier to maintain over the years. Furthermore, the flexibility of channel lining makes it easier to apply for both erosion control and drainage applications, and much less material is needed when compared with concrete channels. Compared to other linings, such as concrete or traditional revetment options, Gabion Supply channel lining requires significantly less maintenance due to its ability to withstand wind and harsh weathering while being extremely abrasion resistant and withstanding the wear and tear of regular use.

Our range of channel lining design solutions and products can guarantee reliable protection, control erosion, and safely deliver drainage wherever needed.

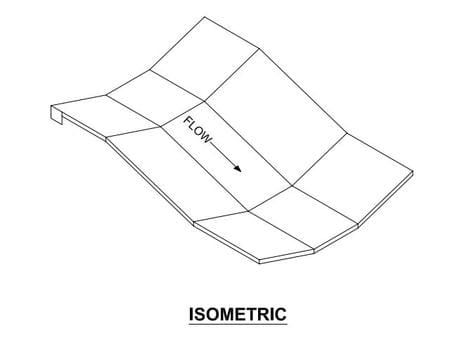

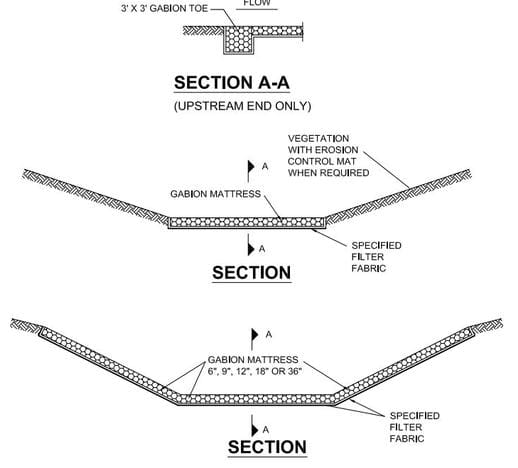

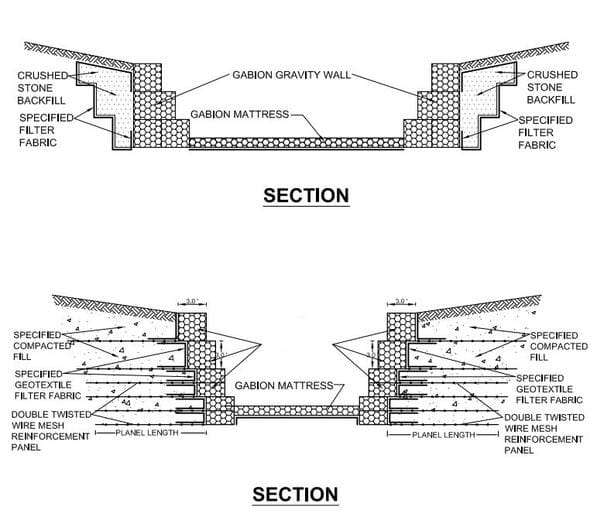

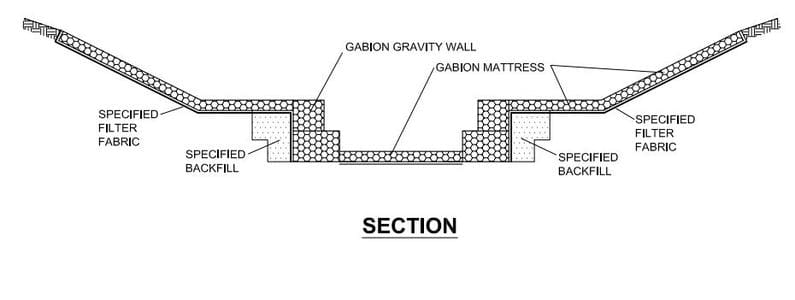

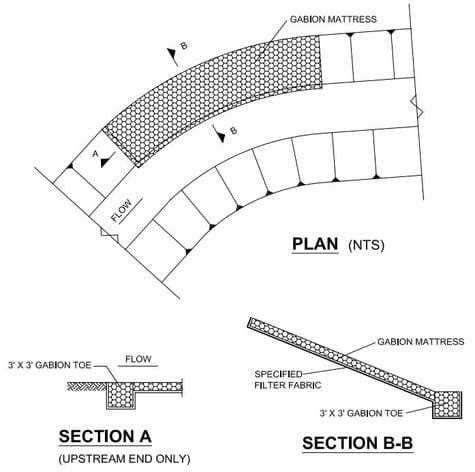

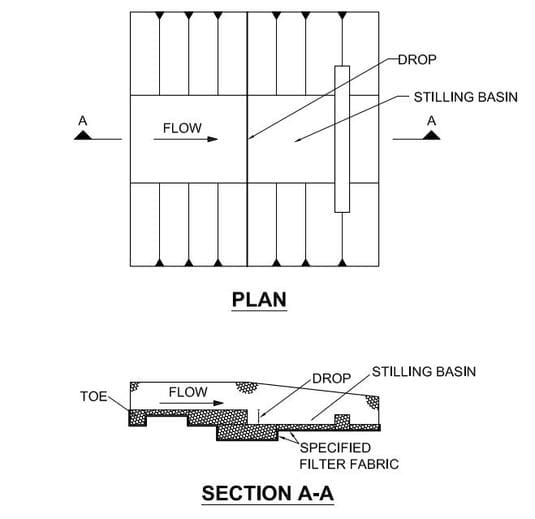

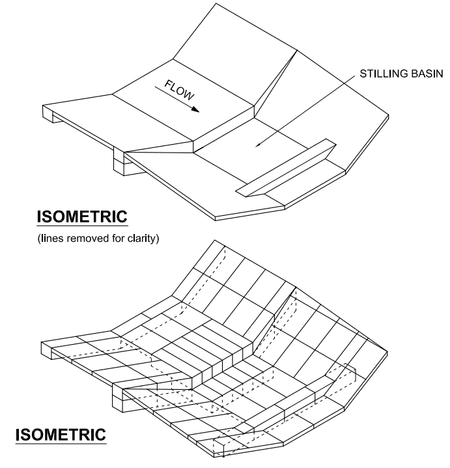

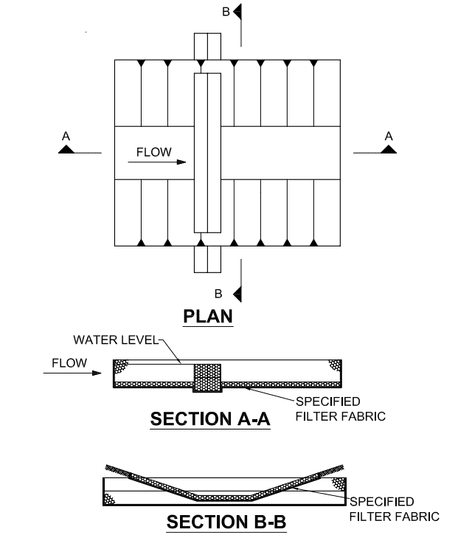

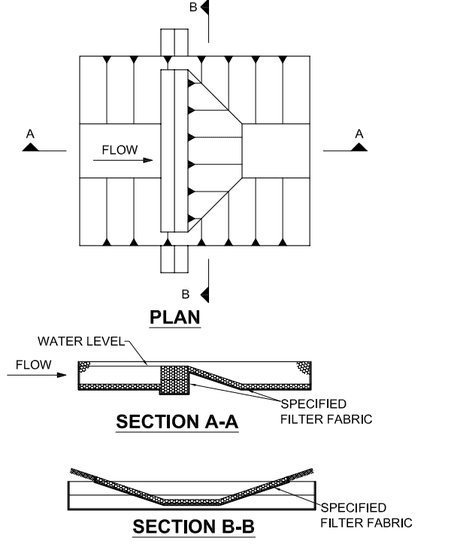

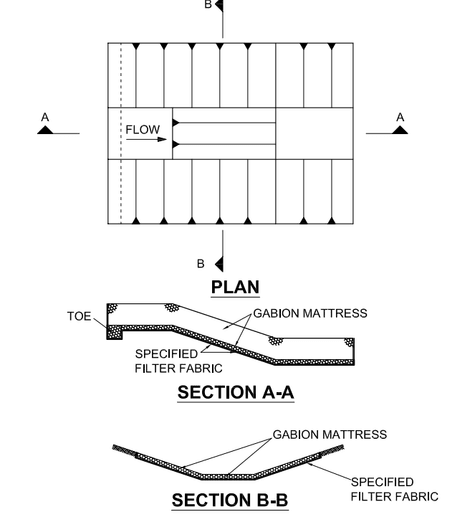

CHANNEL LINING DETAILS

DETAIL #1

DETAIL #2

DETAIL #3

DETAIL #4

DETAIL #5

DETAIL #6

DETAIL #7

DETAIL #8

DETAIL #9

DETAIL #10