Dura-Weld Gabions

GABION SUPPLY is one of the few AMERICAN owned and managed suppliers of pre-assembled Gabion Baskets and Mattresses. Please note that most gabions on the internet are made in China, India, Mexico, Europe and Australia.

We Offer Gabions constructed of

We supply DURA-WELD TM GABIONS ... the highest-quality welded wire mesh products for soil retention, soil stabilization, erosion control, flood management, along with various architectural and landscaping applications

Welded wire mesh construction insures that each point of contact in the grid pattern is welded to form a rigid connection, making this type of gabion material important in achieving a flat, sharp appearance. The added stiffness provided by welded wire mesh and corner stiffeners offers greater resistance to bulging and also makes rock filling less cumbersome

The basic advantage of DURA-WELD™ welded gabions over twisted wire gabions is they are more rigid and can be made of heavier 9 gauge (0.148) or 6 gauge (0.192) wire instead of the standard 11 gauge (0.120) twisted wire gabions. They hold their shape better, will last longer and can be assembled faster resulting in substantial labor savings

GABION SUPPLY is a factory direct supplier with years of experience offering a wide selection of quality constructed Gabion Baskets and Mattresses to meet all your EROSION CONTROL and LANDSCAPING needs

DURA-WELD™ Gabions offer:

Unlike cheap imports, our gabions are quality constructed to conform to:

U.S. Federal Specifications: ASTM A974-97 QQ-W-461H Class 3, ASTM A-641, ASTM A-90, ASTM A-185

STANDARD SIZES - WELDED MESH GABIONS w / 3" x 3" SQUARE MESH OPENINGS

STANDARD MESH: 3" x 3" SQUARE IN 11 & 9 GAUGE WIRE

CUSTOM MESH: 1.5" x 1.5", 2" x 2", 3" x 1.5" OR CALL US IF YOU HAVE A SPECIAL MESH REQUIREMENT

CUSTOM WIRE GAUGES: 6 GAUGE (0.192) or 1/4" (0.250) GALVANIZED, PLAIN STEEL OR STAINLESS STEEL

PLAIN STEEL, GALVANIZED STEEL, GALVANIZED & PVC COATED STEEL & STAINLESS STEEL

STANDARD GAUGE GALVANIZED GABIONS SHIP IN A COUPLE OF DAYS!

OTHER SIZES AND MESH OPENINGS AVAILABLE ON REQUEST

Note: Gabions may be field cut to fit curves, culverts, or angles.

CALL US FOR PRICING AND AVAILABILITY 1-866-391-6295

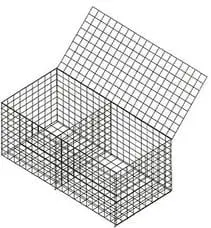

Gabion Supply offers US Made Gabion Baskets and Mattresses fabricated from precision welded corrosion resistant steel wire mesh assembled into square or rectangular cells of varying sizes. The most common Gabion Baskets for a retaining wall measures: 3'x3'x3', 6'x3'x3', 9'x3'x3' and 12'x3'x3' with opening of 3" x 3" in a square pattern

Other sizes, shapes, wire gauges and mesh openings are available upon request

Gabions come to the job site pre-fabricated and knocked down for economy in transportation. They are easily erected, set into place and filled with stone to form a monolithic, flexible structure which provides low cost, long-term erosion control and soil stabilization

The high permeability of gabions eliminates buildup of hydrostatic pressure which will displace and crack rigid concrete structures. Gabions conform to irregularities and dynamics of changing soil conditions without compromising performance

Because of their inherent flexibility, gabion structures can yield to earth movement and retain their full efficiency while remaining structurally sound. They are quite unlike rigid or semi-rigid structures which may suffer complete failure when even slight changes occur in their foundations

Gabion structures act as self-draining units which "bleed" off ground waters, relieving hydrostatic heads. Voids between the stones dissipate the energy from flood, current, and wave action; the entire structure is, therefore, a ”breathing," self-draining unit needing no additional drainage. Gabion efficiency, rather than decreasing with age, actually increases. During early periods of use, silt and vegetation will collect within the rock filling to form a naturally permanent structure, enhancing the environment

One of the first gabion structures installed in Europe at the turn of the century for river works was examined after 75 years in service and found to be in perfect condition. From an economic perspective, finished gabion work is invariably less expensive than a conventional structure

The cost of gabions and stone fill is nominal; unskilled laborers can be used in construction; the high cost of underwater excavations, driving piling and underground drainage systems is avoided.

Gabions are virtually maintenance free and construction speed is hastened because no forms, reinforcements, setting or curing time are necessary.

PVC COATED GABIONS

The same specifications for galvanized gabions apply with the additional polyvinyl chloride (PVC) coating which will be fuse bonded onto the welded mesh as follows:

Mesh Wire .......................... core only . 0.106" (2.7 mm)

Spiral Binders ..................... core only ... 0.106(2.7 mm)

Lacing Wire & Twist Ties .... core only ... 0.087(2.2 mm)

PVC Coating Thickness0.015" (0.4 mm) minimum per side

RESISTANCE OF THE COATING. The protective coating must be resistant to the destructive effects of immersion in acidic, salt, or polluted water, exposure to ultraviolet light and abrasion and shall retain these characteristics after a period of not less than 3,000 hours under tests in accordance with ASTM G-23.

GENERAL SPECIFICATIONS -WELDED STEEL WIRE MESH - GALVANIZED GABION MATTRESS

MATERIAL. Gabion mattresses shall be made of welded steel wire mesh of a nominal size of 1-1/2" x 3(3.8 cm x 7.5 cm). Gabion mattress units shall be supplied in various lengths. The thickness shall be 6", 9", 12" or 18". The horizontal width shall be 6'. All dimensions are subject to a tolerance of ± 5% of manufacturer's stated sizes.

FABRICATION. Gabion mattress units shall be fabricated in such a manner that the base, sides, lids, ends, and diaphragms can be assembled at the construction site into a rectangular unit of the specified size. The mattress unit length shall be subdivided into 3' compartments by the insertion of diaphragms made of the same mesh as the rest of the mattress.

The wire incorporated in the mesh constituting the body of the mattress shall be made of galvanized steel wire having a diameter of 0.087" (2.2 mm). Preformed steel wire spiral binders with a 3" pitch are used to assemble and interconnect empty gabion mattresses and shall meet the same specifications as the wire used in the mesh. All wire used in the fabrication of gabion mattresses and in the wiring operations shall conform to ASTM A-974-97 and US federal specifications QQ-W-461H and possess a soft tensile strength with a class 3 finish 5 zinc coating in accordance with ASTM A-641.

After assembly, the individual mattress units are interconnected to each other as per manufacturer's instructions and then filled with clean, hard stone from 3'- 6" in diameter. The lids are then placed and spiraled to the top edges of the individual gabion mattresses and diaphragms. Ring fasteners, twist ties