"DURA-GUARD™ GABIONS LAST A LIFETIME IN SALT WATER"

GABION SUPPLY IS THE EXCLUSIVE U.S. SUPPLIER OF DURA-GUARD™ MARINE GABION BASKETS AND GABION MATTRESSES

DURA-GUARD™ MARINE GABIONS ARE CONSTRUCTED OF DURABLE, NON-CORROSIVE AND ENVIRONMENTALLY FRIENDLY CO-POLYMER GEO-GRID PANELS.

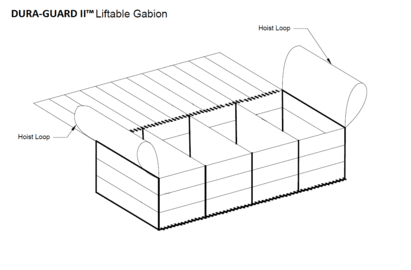

DURA-GUARD II™ IS A HYBRID GABION CONSTRUCTED OF A STAINLESS STEEL CAGE LINED WITH THE SAME GEO-GRID PANELS AS OUR STANDARD DURA-GUARD™ GABIONS

GEO-GRID PANELS ARE EXTENSIVELY USED IN THE CONSTRUCTION OF RETAINING WALLS, BRIDGE ABUTMENTS, ROADWAYS AND SOIL STABILIZATION APPLICATIONS. DURA-GUARD™ GABIONS ARE AVAILABLE IN SQUARE, RECTANGULAR, WEDGE OR BARREL SHAPED UNITS.

EXAMPLES OF GEO-GRID MATERIALS

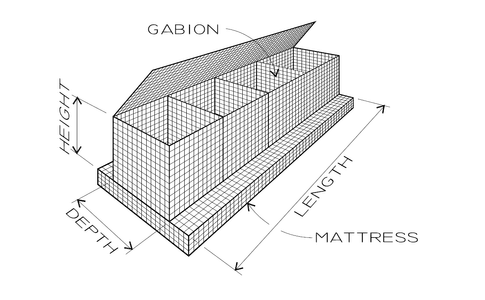

DURA-GUARD™ MARINE MATTRESSES are available in various styles and thicknesses to meet specific project requirements and provide a durable, non-corrosive solution to many coastal and inland waterway erosion problems.DURA-GUARD™ MARINE MATTRESSES are available in various styles and thicknesses to meet specific project requirements and provide a durable, non-corrosive solution to many coastal and inland waterway erosion problems.

DURA-GUARD™ Marine Cells are circular gabions constructed of high strength co-polymer panels that can be filled with durable materials such as rocks, broken concrete, oyster shells, etc. Lining them with geo-textile fabric or inserting bulk poly bags enables filling with sand or other fine-grained materials.These cells can be filled rapidly, thus reducing de-watering time and saving labor hours.

DURA-GUARD™ Marine Cells can dissipate wave/tidal energy, increase bearing capacity and load distribution.

Applications include: Sea walls, bulkheads (new and rebuilds), check dams, breakwater cores, jetties and dikes, foundations and containment dikes for dredge spoils or other waste materials.

DURA-GUARD™ Marine Cells feature: Durable, high strength, non-corrosive materials, UV resistant, fast filling and will last a lifetime in salt water

FEATURES:

- IMMUNE TO SALT WATER, ACIDIC and ALKALINE ENVIRONMENTS

- EXCELLENT DURABILITY

- HIGH ABRASION RESISTANCE

- IMMUNE TO ROT, MILDEW AND MARINE ORGANISMS

- HIGH TENSILE STRENGTH

- HIGH THERMAL STABILITY

- UV STABILIZED

- HIGH FLEXIBILITY - CONFORMS TO IRREGULAR SURFACE CONTOURS

Introduction to DURA-GUARD™ Marine Gabions

At Gabion Supply, we understand the challenges of shoreline stabilization and coastal protection. That’s why we developed DURA-GUARD Marine Gabions, an innovative solution designed to withstand harsh marine environments while supporting natural vegetation growth and long-term ecosystem stability.

DURA-GUARD gabions provide a durable, environmentally friendly way to protect coastlines, riverbanks, and other marine settings from erosion. Traditional methods, such as concrete seawalls, often disrupt ecosystems and require frequent maintenance. In contrast, our easy-install marine gabions offer a flexible, long-lasting alternative that blends seamlessly with natural surroundings. Whether you're working on a large-scale infrastructure project or a smaller shoreline restoration effort, DURA-GUARD gabions deliver effective, sustainable stabilization.

DURA-GUARD™ gabions are relatively low in cost and due to their flexible and porous construction they are able to absorb wave and wind energy, thereby reducing the scour problems associated with rigid sea defenses such as concrete seawalls.

DURA-GUARD™ gabions can be placed as sloping “mattresses” or as as a base for near vertical walls constructed of stacked courses of gabion baskets.

DURA-GUARD™ marine gabions are durable and more economical than type 316L stainless steel. They are resistant to salt water corrosion and all naturally occurring forms of chemical, biological and environmental degradation.

Typical Applications:

● Coastal Erosion Control Projects

● Shore Protection and Sediment De-Watering

● Channel Linings

● Check Dams

● Bridge Scour Protection

● Breakwater Foundations or Cores for Breakwaters

● Causeways, Levees, Dikes and Bridge Approach Projects

● Bio-Swale Runoff Filters and Sediment Collectors

● Situ Capping of Contaminated Sediments

● High-Strength Reefs and Fills Constructed in Submerged Conditions

PERFORMANCE:

DURA-GUARD™ gabions provide increased hydraulic performance and construction advantages ... also more economical than conventional solutions such as riprap and stainless steel.

They also conform to land contours and site configurations while resisting scour far better than ridgid systems. Because the co-polymer grids resist all naturally occurring forms of chemical, biological and environmental degradation, they are often specified for salt water, industrial run-off conditions and contaminated sediment capping where other types of materials would deteriorate rapidly.

Features and Benefits of DURA-GUARD Marine Gabions

DURA-GUARD gabions are built to withstand the unique challenges of marine and coastal environments. Our corrosion-resistant gabions ensure long-term performance even in saltwater conditions, making them ideal for shoreline stabilization projects.

Key benefits of DURA-GUARD Marine Gabions include:

- Corrosion resistance: Constructed with high-quality materials that resist rust and degradation in wet environments, especially in the salt air of the seashore

- Shoreline stabilization: Helps protect against erosion by dissipating wave energy and reinforcing shorelines

- Support for natural vegetation growth: Encourages plant growth as close to the shoreline as possible, which further stabilizes local soil and promotes overall healthier coast ecosystems

- Easy installation: Designed for quick, efficient deployment, which saves you time and reduces labor costs by a wide margin

- Environmentally friendly: A sustainable alternative to concrete and other hardscape erosion control methods

By using standard gabions or customizing our DURA-GUARD models to your project’s specific needs, we provide functional and eco-conscious solutions.

Why Choose DURA-GUARD by Gabion Supply?

At Gabion Supply, we're committed to delivering high-quality solutions that help stabilize ecosystems and protect valuable coastal landscapes. With decades of expertise in gabion design and engineering, we provide durable, cost-effective products tailored to meet the demands of marine applications.

When you choose DURA-GUARD Marine Gabions, you get:

- Industry expertise. We have years of experience in erosion control and shoreline stabilization, which we're ready to put to your service when you call for a consultation.

- Customizable options. We offer several standard and highly customizable gabion designs to fit your project’s needs.

- Reliable support. A team of professionals is ready to assist with your product selection and give helpful installation guidance.

Protecting shorelines and marine environments requires durable, adaptable solutions. With DURA-GUARD by Gabion Supply, you can trust your coastal protection efforts will stand the test of time. Contact us today to learn more about how DURA-GUARD can benefit your next project.