M.S.E. RETAINING WALLS

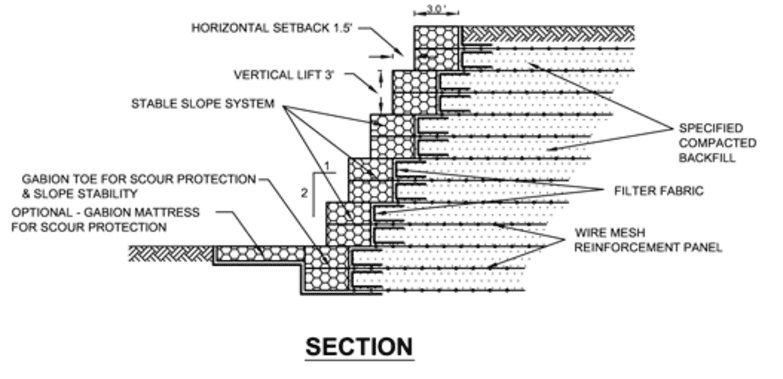

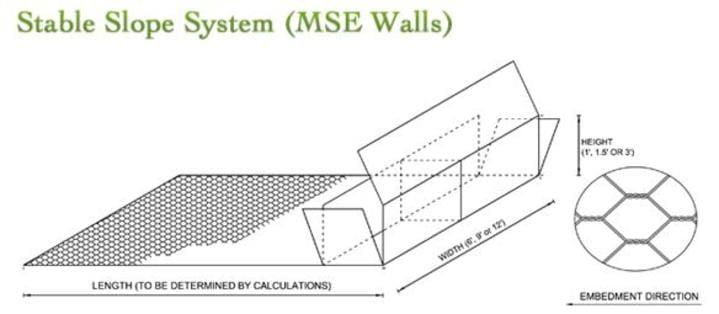

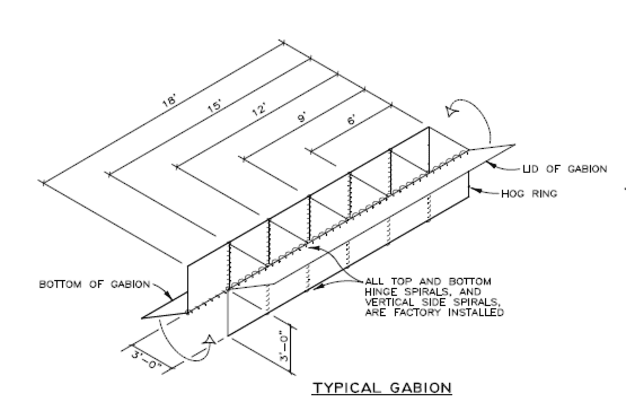

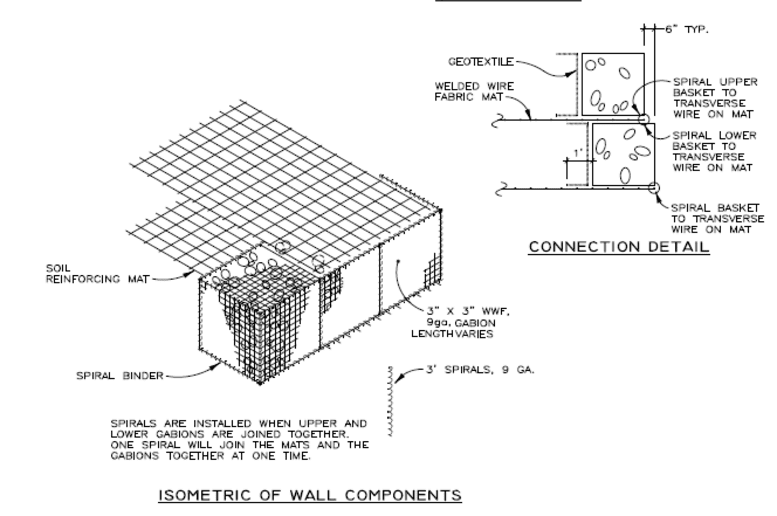

Mechanically Stabilized Earth Walls (M.S.E.) are reinforced gabion walls constructed using multiple courses of DURA-WELD™ or DURA-FLEX™ Gabion baskets integrated with flat steel wire mesh panels or GEO-GRID geosynthetic layers placed horizontally between the layers of gabions to lock into a slope with compacted backfill on top.

MSE retaining walls are a modern alternative to the conventional reinforced concrete retaining wall, and have a number of advantages over concrete retaining walls.

MSE retaining walls consist of soil, reinforcing elements, precast concrete blocks, and wall facing. They are well-suited for curved applications, making them versatile and ideal for areas where it is difficult to bring in large pieces of heavy equipment.

What Is a Mechanically Stabilized Earth Retaining (MSE) Wall?

An MSE wall uses soil reinforcement elements and compacted backfill fixed to a wall facing to create a solid structure. It's often used in freeways, as bridge abutments, and is installed in riverbanks and dams. Its straightforward construction process makes it a preferred retaining wall structure even in homes and businesses. Choosing the right materials for a mechanically stabilized earth wall depends on aesthetics, application, and other factors. MSE wall has three main components.

Facing

Depending on the application, concrete is a commonly used material for facing along with gabions, welded wire forms (black steel or galvanized), or segmental retaining wall blocks. The MSE wall's facing keeps the other components (backfill and soil reinforcement) in place, supporting the entire structure. The facing is relatively thin and prevents the backfill and soil reinforcement from corroding. Types of facing you can use include cruciform, square, sloped, full-height rectangular, and permanent or temporary wire mesh.

Soil Reinforcement

Geosynthetic strips, geogrids, and galvanized steel mesh are soil reinforcements that hold the backfill and keep it from moving or shifting. They connect to both the facing and backfill and are the glue that holds the composite structure together. Geosynthetic strips, geogrids, or galvanized steel mesh are required for the MSE wall; without them, you'll need a thicker facing, which can cost more money and take longer to build.

Backfill

The backfill is the main force on the MSE wall and is supported by the reinforcement and the facing. Soil is a common material used because it allows for easy compaction. Recycled materials like crushed concrete are also used as backfill. Lightweight materials, such as foamed glass aggregate or low-density cellular concrete, may also be used.

Benefits of an MSE Wall

Compared to other retaining walls, an MSE block wall requires less preparation and doesn't require curing time or additional finishes. It's a popular option because it offers several benefits.

Cost-Effective: The materials used for building MSE walls are more cost-effective than a fully concrete structure. You can also use a wide range of materials for your soil reinforcements and backfill (including lightweight materials that cost less). Building a mechanically stabilized earth retaining wall may be the best option if you want an affordable yet durable retaining wall.

Easier to Install Than Concrete: MSE walls are easier to build, offering minimal disruptions and helping you save time. They also don't require complex preparations or additional support, making them a popular retaining wall alternative to concrete. Go for an MSE wall if you prefer a project that's easier and quicker to complete. Its strength and durability make it an even better option.

Aesthetics: One of the advantages of installing an MSE wall is that it can be customized. You can choose different types of materials for the facing to ensure they match the style of the surrounding structure or area. You also don't need specialized workers or heavy machinery to build it. Contact us if you need help choosing the right type of material for the facing.

Flexibility: MSE walls can shift with the earth or ground, making it the most flexible retaining wall you can install. You don't have to worry about the wall sinking or cracking when the soil expands. Also, because it's flexible, you can even build extremely high MSE retaining walls.

Resistant: MSE walls can resist lateral bearing pressure from the earth and are highly resistant to seismic activity and hydrostatic pressure. They transfer the pressure over a broader area, ensuring durability even in earthquake-prone areas.

Weight Capacity: MSE walls are often installed in high-volume traffic areas because they can withstand extremely heavy loads, such as crane loads, bridge abutment footings, or service loads. There's no need to worry about having really tall walls because they distribute the weight to the entire area, ensuring the structure's stability.

MSE Wall Applications

MSE retaining walls can be employed in a variety of applications. They can be used as temporary structures, such as in highway projects or for containment structures. They are also used in dam, dike and levee construction. Other applications include bridge abutments, wing wall systems, and the creation of storage areas.

MSE Solutions from Gabion Supply

Gabion Supply offers materials for various types of Mechanically Stabilized Earth (MSE) and Reinforced Steep Slope (RSS) Systems. These solutions provide our clients with an array of aesthetics and facing options, allowing for the most cost-effective use of land while achieving maximum architectural and environmental value. We offer economical alternatives to traditional building materials that incorporate high-performance geo-synthetic products and High-Density Polyethylene (HDPE) soil reinforcement systems.

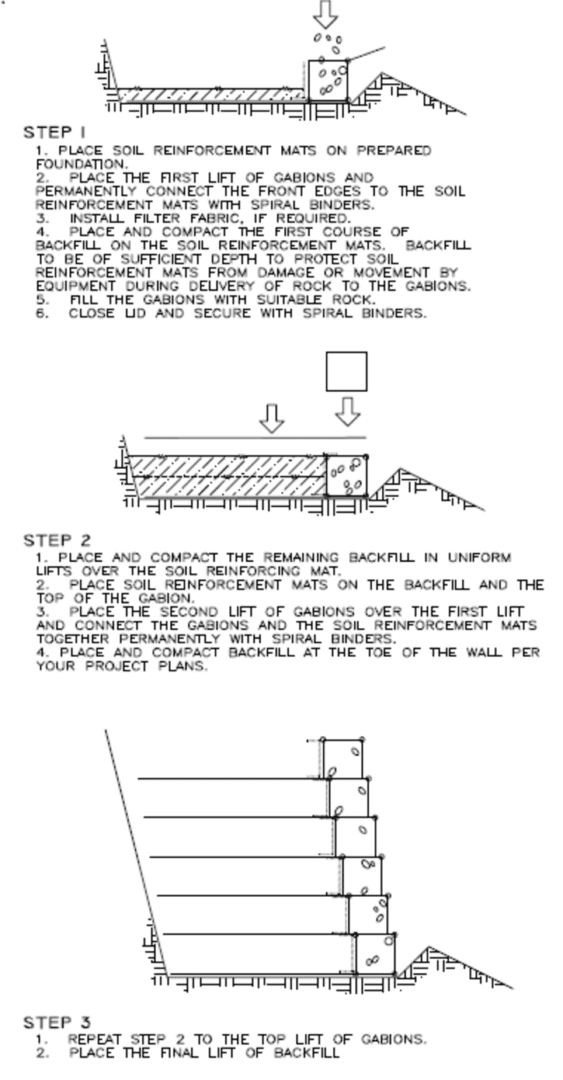

BUILDING AN M.S.E. RETAINING WALL

MSE gabion walls afford important advantages:

- Permeability of the front face and drainage of the backfill

- Flexibility: enabling the structure to tolerate differential ground settlement without compromising structural integrity

- Versatility: allows the formation of a structure with vertical, battered or stepped front face as required and minimized environmental impact

- Durability: testimonials of existing gabion structures built since 1894 and still in operation prove that MSE structures can be safely designed for 120 years design life

- Economy: construction does not require specialized labor or equipment

- Filling: gabions are filled with natural or quarried stones obtained locally with minimum foundation preparation

- Structural safety in the event of fire near the front face

- Reduction of environmental impact through the use of vegetation planted into the front face of the structure