PVC COATED GABIONS

PVC COATED GABIONS

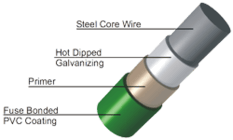

The same specifications for galvanized gabions apply with the additional polyvinyl chloride (PVC) coating which will be fuse bonded onto the welded mesh as follows:

Mesh Wire ....................... core only . 0.106" (2.7 mm)

Spiral Binders .................. core only ... 0.106(2.7 mm)

Lacing Wire & Twist Ties .... core only ... 0.087(2.2 mm)

PVC Coating Thickness 0.015" (0.4 mm) minimum per side

RESISTANCE OF THE COATING

The protective coating must be resistant to the destructive effects of immersion in acidic, salt, or polluted water, exposure to ultraviolet light and abrasion and shall retain these characteristics after a period of not less than 3,000 hours under tests in accordance with ASTM G-23.

SPECIFICATIONS -WELDED STEEL WIRE MESH - GALVANIZED GABION MATTRESS MATERIAL

a) General: Gabion mattresses shall be made of welded steel wire mesh of a nominal size of 1-1/2" x 3(3.8 cm x 7.5 cm).

b) Dimensions: Gabion mattress units shall be supplied in various lengths. The thickness shall be 6", 9", 12" or 18". The horizontal width shall be 6'. All dimensions are subject to a tolerance of ± 5% of manufacturer's stated sizes.

FABRICATION

Gabion mattress units shall be fabricated in such a manner that the base, sides, lids, ends, and diaphragms can be assembled at the construction site into a rectangular unit of the specified size. The mattress unit length shall be subdivided into 3' compartments by the insertion of diaphragms made of the same mesh as the rest of the mattress.

The wire incorporated in the mesh constituting the body of the mattress shall be made of galvanized steel wire having a diameter of 0.087" (2.2 mm). Preformed steel wire spiral binders with a 3" pitch are used to assemble and interconnect empty gabion mattresses and shall meet the same specifications as the wire used in the mesh. All wire used in the fabrication of gabion mattresses and in the wiring operations shall conform to ASTM A-974-97 and US federal specifications QQ-W-461H and possess a soft tensile strength with a class 3 finish 5 zinc coating in accordance with ASTM A-641.

After assembly, the individual mattress units are interconnected to each other as per manufacturer's instructions and then filled with clean, hard stone from 3'- 6" in diameter. The lids are then placed and spiraled to the top edges of the individual gabion mattresses and diaphragms. Ring fasteners, twist ties and lacing wire can be used in lieu of spiral binders.

PVC COATED GABION MATTRESSES

The same specifications as for galvanized gabion mattresses apply with the additional polyvinyl chloride (PVC) coating which will be fuse bonded onto the welded mesh as follows:

Mesh Wire .................. core only ...... 0.087" (2.2 mm)

Spiral Binders ............. core only ......... 0.106(2.7 mm)

Lacing Wire & Twist Ties....core only ..... 0.087(2.2 mm)

PVC Coating Thickness0.015" (0.4 mm) minimum per side

RESISTANCE OF THE COATING

The protective coating must be resistant to the destructive effects of immersion in acidic, salt, or polluted water, exposure to ultraviolet light and abrasion and shall retain these characteristics after a period of not less than 3,000 hours under tests in accordance with ASTM G-23.Welded Steel Wire Mesh Gabions & Gabion Mattresses conforming to ASTM A974-97 US Federal Specification QQ-W-461H Class 3, ASTM A-641, ASTM A-90, ASTM A-185